General information on hot-air welding machines:

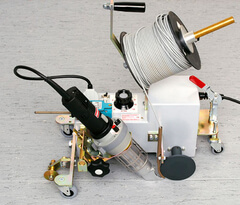

A hot air welding machine is an automated welding machine that uses hot air welding technology to join different materials together.

These machines are particularly widespread in the plastics processing industry, as they offer a precise and efficient method of welding plastics.

How it works:

- The hot-air welding machine is based on hot-air welding technology, in which a permanent joint is created by heating and melting materials.

- A hot air blower generates a controlled air flow that is directed through a heating element.

- The heated air is then directed onto the material to be welded in order to bring it to melting temperature .

- The materials are then pressed together and fused to create a solid bond.

Features of a hot-air welding machine:

- Temperature control:

Modern hot air welding machines have precise temperature controls to ensure the optimum welding temperature for different materials.

Air flow control:

Controlling the air flow is important to ensure that the heated air is directed evenly onto the materials to be welded.

Automation:

A hot-air welding machine can be partially or fully automated, enabling repeatable and high-precision welding processes.

Pressure control:

The ability to adjust and control the welding pressure ensures uniform fusion of the materials.

Material adaptation:

The machine should be able to adapt to different materials and material thicknesses to enable a wide range of applications.

Security features:

Hot-air welding machines can be equipped with safety functions such as emergency stop switches and overheating protection to ensure safe operation.

Applications of a hot-air welding machine:

Plastics processing:

In the plastics industry, hot air welding machines are often used to weld plastic components, whether in the manufacture of containers, pipes, packaging or other plastic products.

textile industry:

Hot air welding machines are used in the manufacture of textile products, where they can weld lengths of fabric together.

Automotive industry:

Hot-air welding machines can be used for the production of plastic parts in vehicle construction, such as dashboards or interior trim.

construction industry:

Hot air welding machines can be used in the production of plastic films, covers or membranes for construction projects.

Medical applications:

In medical technology, hot-air welding machines are used for the production of medical devices and packaging.

Hot air welding machines offer an efficient and precise method of welding materials, especially plastics, and are widely used in various industries.