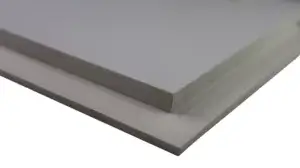

Polyvinyl chloride-chlorinated

PVC-C for short , is a special form of chlorinated polyvinyl chloride (PVC-C or CPVC), which is produced by the chlorination of PVC.

Properties of PVC-C:

- Chemical resistance:

PVC-C is characterized by excellent chemical resistance, especially to acids, bases and many chemicals. This feature makes it ideal for use in demanding industrial environments. - Temperature resistance:

PVC-C can withstand higher temperatures than conventional PVC (polyvinyl chloride). It remains more stable at higher temperatures (compared to PVC), which makes it suitable for applications in hot water pipes and industrial processes. - Fire resistance:

PVC-C is flame retardant and meets high fire protection requirements. This makes it attractive for use in safety-critical applications. - Electrical insulation:

PVC-C is a good insulator and is used in the electrical industry for the manufacture of electrical components. - Mechanical strength:

PVC-C shows good mechanical strength and is therefore suitable for applications where strength and durability are important. - Good processability:

PVC-C is easy to process and can be formed by various methods such as extrusion, injection molding and compression molding.

Applications of PVC-C:

PVC-C is used in various industries for specific applications, including:

- Chemical industry :

Pipes, tanks and fittings due to its chemical resistance. - Building industry :

Hot water pipes, industrial piping, ventilation systems and other construction elements. - Electrical industry :

Insulators, electrical enclosures and other components where good electrical insulation is required. - Automotive industry :

Applications where increased temperature resistance and chemical resistance are required.

Due to its specific properties, PVC-C is a high-performance material in various technical applications, especially in areas that place high demands on chemical resistance and temperature resistance.